What is the ADTANCE Fieldstreaming Solution?

The ADTANCE Fieldstreaming Solution describes the possibility to monitor complete machines, plants and production lines with the help of stationary cameras.

Unlike previously, when using the ADTANCE Remote Support Solution, our customers or their service technicians can no longer just access a section of the image that is recorded by a pair of data glasses or another mobile end device. If stationary cameras are positioned around a machine and connected to ADTANCE Support, the service technician can also view larger areas of a plant via live video stream or even overlook entire production plants. Drones can also be connected to ADTANCE Support. These enable a bird's eye view of larger machines, for example. The connection of Underwater Remote Operated Vehicles (ROVS) can be used for viewing parts that are underwater, e.g. for inspecting the hull of a ship.

What does the ADTANCE Fieldsteaming Solution Include?

We offer the Fieldstreaming Solution in the form of a hard case (Streamings Case) equipped with any number and type of cameras.

The streaming case also contains a power supply unit for connection to the power supply, an internet cable for connection to the internet, connection cables for connecting each camera to the streaming case and a server.

The service connects all cameras to the ADTANCE support solution.

How does the ADTANCE Fieldstreaming Solution Work?

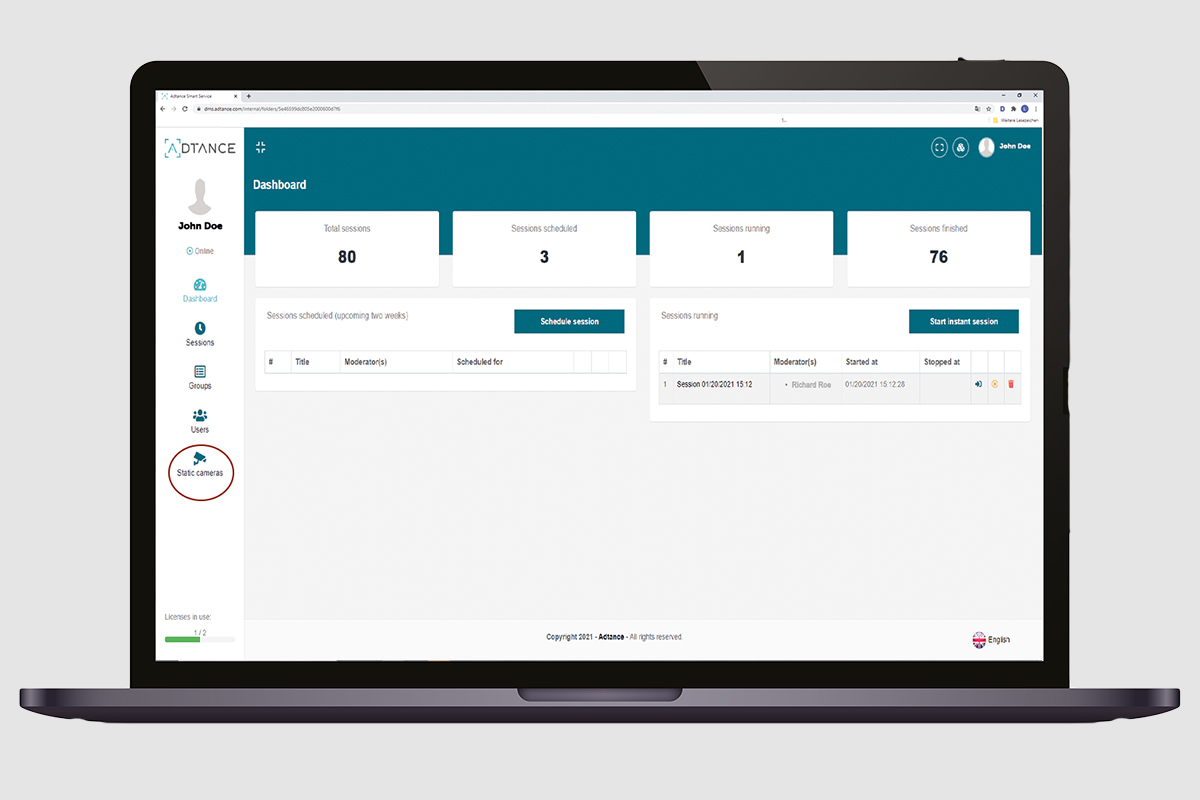

When commissioning the Fieldstreaming Solution on site, the Streaming Case must first be connected to power and the Internet and the cameras must be connected to the Streaming Case with the enclosed connection cables. The Streaming Case can then be switched on. Once the case is powered up with the cameras connected, it is ready to use and will show as connected in the platform.

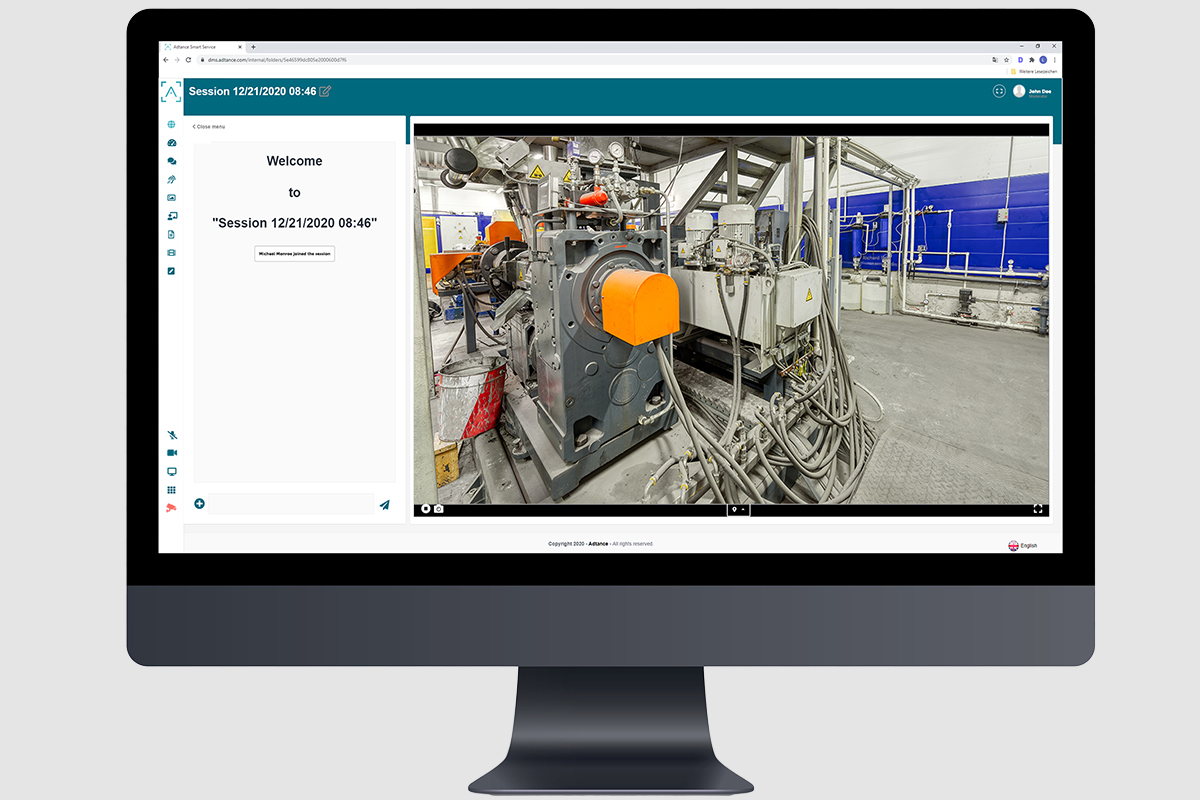

With ADTANCE Support, the stationary cameras can now be controlled remotely by a service technician or other staff member. For automated and moving cameras, this means that the viewing or tilt angle and zoom can be controlled remotely. The worker can thus gain a holistic overview of a machine on his desktop screen, as well as view specific smaller sections of a machine from different angles. With non-automated cameras, only the zoom can be controlled remotely, but not the tilt angle of the cameras. If several cameras are connected to ADTANCE Support, the images from all cameras can be viewed simultaneously in the grid or carousel view within the support solution. In the grid view, all camera images can be displayed on the screen in the same size. In the Carousel View, a selected camera image is displayed large, while all other images are displayed small under the large image. In addition to stationary cameras, cameras from data glasses, mobile devices, drones, etc. can also additionally be connected in the same ADTANCE Support session. For example, an employee wearing data glasses can get better or more specific shots of hard-to-reach areas on a machine in addition to the all-around view provided by the stationary cameras. The service technician, co-worker or colleague can provide assistance and instructions accordingly.

Use Cases - What is the ADTANCE Fieldstreaming Solution Needed for?

Especially in times of Corona, when whoever can, should stay at home, the concept of the Fieldstreaming Solution has gained importance. Our customers use the solution e.g. for pure monitoring of machines, to analyze them and to optimize processes, for trainings and the acceptance of components.

For training courses and the acceptance of components, the cameras are set up on site at our customers' premises (e.g. a machine or component manufacturer).

In the context of an employee training, for example, several of the stationary cameras can be placed around the machine on which the employees are to be trained. All employees can participate in the training from their homes or offices by following the invitation link. The cameras positioned around the machine allow the participants to have a complete view of the machine and switch between the different camera views to get different angles. For example, the trainer can first give the participants an overview of the machine.

If the training then goes into more depth and specific components and individual parts need to be viewed, the trainer can also use smartglasses for example. The video recording from the smartglasses is also transmitted to the training participants. This allows them to see exactly which component the trainer is currently working on by virtually looking over his shoulder. At the same time, the participants can view the live-recordings from the stationary cameras to better identify and arrange the machine area where the trainer is located. This can be particularly useful for very large plants or production lines, where the video transmission of the trainer's field of view alone makes it difficult to determine exactly where the trainer is located in the plant.

The stationary cameras positioned around a component during a acceptance also enable the customer or expert to view the component from different angles at the same time. A component inspection with the addition of several stationary cameras instead of just one pair of smartglasses is even closer to an on-site inspection, since these offer the customer or expert a view of the component from all possible perspectives and can convey a better overall impression. However, the data glasses can also be added here.

Furthermore, the Fieldstreaming Solution can be used for indoor and outdoor assembly, installation and commissioning of a machine or an entire production line. By placing several cameras at the assembly site and possibly adding smartglasses and other mobile devices, the experts sitting at the company site can follow the assembly, installation and commissioning of the machine, share their know-how for specific parts of the assembly and commissioning with the employees on site and instruct or support them.

The Fieldstreaming Solution with ADTANCE Support is also used for normal service cases, such as repairs and maintenance from a distance-as is already known from the use of the ADTANCE Support solution with data glasses. In contrast to smartglasses, the Fieldstreaming Solution offers the advantage of a holistic view of the machine/plant, which a machine operator wearing smartglasses or a mobile device could not provide.

Advantages of the Fieldstreaming Solution

As already mentioned, the Fieldstreaming Solution offers a holistic view of machines or even entire production lines, in contrast to smartglasses or other mobile devices that only record a limited field of view or a specific image section. By connecting several stationary cameras, different perspectives and angles can be viewed. This provides a holistic overview of the machine, as well as - through the zoom options - detailed views of machine sections.

In addition, the Fieldstreaming Solution not only saves a lot of travel costs, companies can also counteract the shortage of skilled workers. By eliminating the need for travel and saving time, specialized employees can take on more tasks, such as service cases that arise, and solve customer problems more quickly. This means that specific know-how from experts can be used even more efficiently.

In pandemic times, companies can protect employees by using the Fieldstreaming Solution to avoid high travel volumes and allow experts to handle service cases, installations, startups and other tasks that otherwise require travel from the office or even the home office.

What Else?

The above examples are just a sampling of uses for the ADTANCE Fieldstreaming Solution. Our customers are already using the solution in this or similar ways. Of course, there are many more possible applications and probably many that we at ADTANCE don't even know about yet.

So feel free to come to us with your use case. We will be happy to present the ADTANCE Fieldstreaming Solution to you in the context of your specific use case, answer any questions that may arise, and work with you to put together a streaming case with the cameras you require. Contact us and you will find the perfect solution for your individual use case. We look forward to talking to you!

Contact us: